The U.S. Department of Commerce on Monday revealed its intention to provide $1.5 billion in direct funding to GlobalFoundries under the U.S. CHIPS and Science Act. Additionally, the company is set to receive over $600 million in support from the state of New York over the next decade to aid in its growth and modernization efforts. This financial support will enable GlobalFoundries to upgrade existing manufacturing capacities in the U.S. and build new ones to meet the demand for U.S.-made chips in automotive, aerospace, defense, and other industries.

GlobalFoundries said it has a $12 billion investment plan for its U.S. manufacturing sites over the next decade that involves public-private partnerships with federal and state governments and strategic ecosystem partners. The company said that this investment package is expected to help it meet the increasing demand for domestically produced chips and create over 1,500 manufacturing jobs and approximately 9,000 construction jobs.

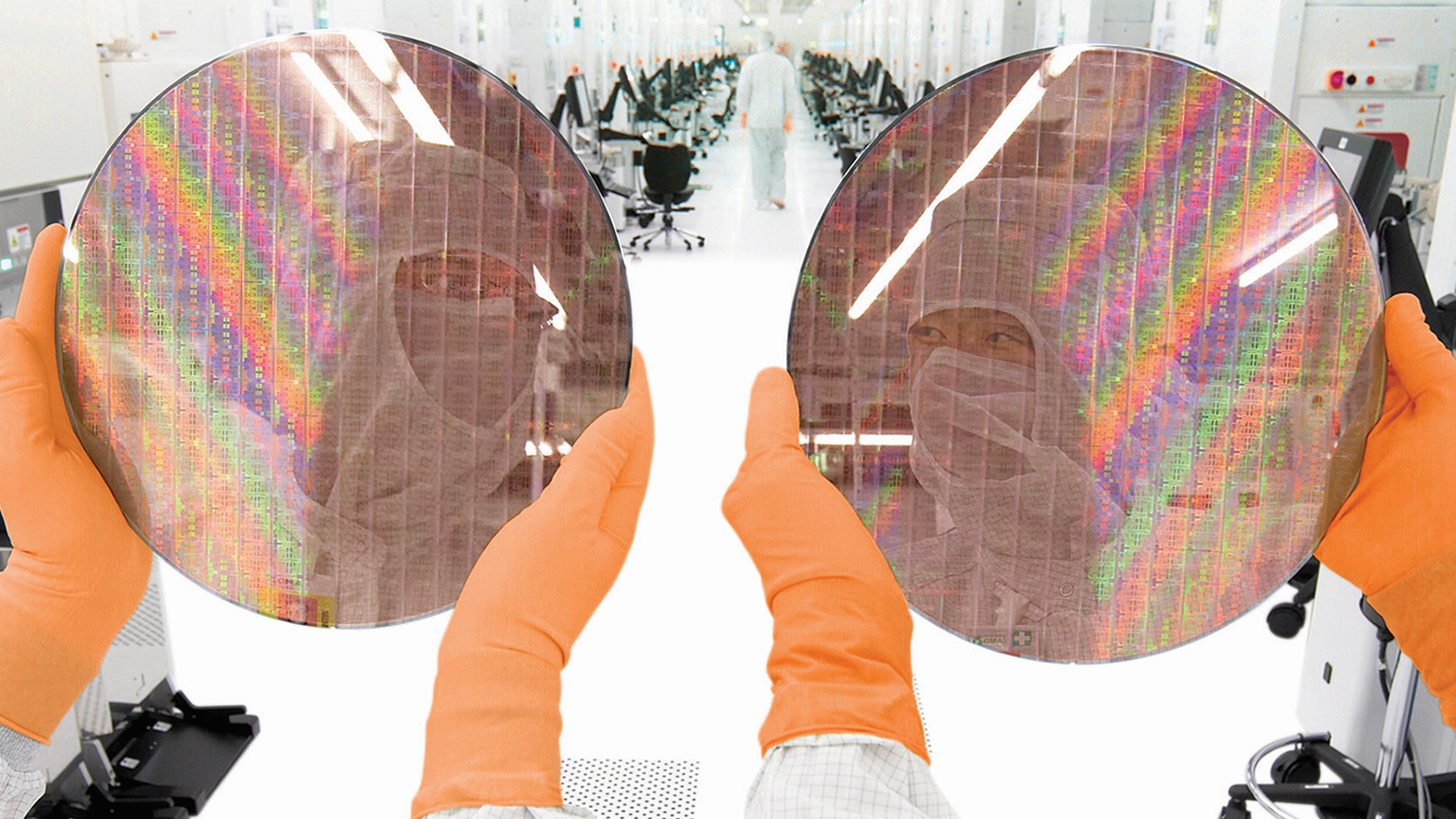

By supporting GlobalFoundries and encouraging it to invest in American semiconductor facilities, the U.S. government boosts the competitiveness and strength of the U.S. semiconductor industry, which is among the key purposes of the CHIPS and Science Act. GlobalFoundries has outlined three key projects to invest in in the upcoming quarters.

First, the company intends to expand its Fab 8 in Malta, NY, to manufacture chips for automotive applications using fabrication technologies already in use at its facilities in Germany and Singapore, which essentially means bringing trailing nodes to Fab 8. This upgrade is vital for meeting the growing demand from the automotive sector as it transits to electric and software-defined vehicles. Additionally, the project will broaden the scope of GloFo’s Malta fab and increase its importance for important fundamentals, such as automotive.

Second, GlobalFoundries intends to construct an all-new fab module on its Malta campus. This upcoming facility aims to satisfy future demand for chips made in the U.S., catering to a variety of sectors such as AI, automotive, aerospace, and defense. The establishment of this new facility, coupled with the enlargement of the existing fab, is projected to triple Malta’s present output to over one million wafer starts per year over the next ten years, which equals approximately 83,300 wafer starts per month (WSPM).

Last, the company aims to revamp its Essex Junction, Vermont facility by upgrading existing fab tools, expanding capacity, and installing tools needed to mass-produce next-generation gallium nitride (GaN) chips whose usage is growing in various applications such as electric vehicles, data centers, communications, and power grids.

“These proposed investments, along with the investment tax credit (ITC) for semiconductor manufacturing, are central to the next chapter of the GlobalFoundries story and our industry,” said Dr. Thomas Caulfield, president and CEO of GlobalFoundries. “They will also play an important role in making the U.S. semiconductor ecosystem more globally competitive and resilient and cements the New York Capital Region as a global semiconductor hub. With new onshore capacity and technology on the horizon, as an industry we now need to turn our attention to increasing the demand for U.S.-made chips, and to growing our talented U.S. semiconductor workforce.”

Companies like AMD, Qualcomm, General Motors, and Lockheed Martin have praised the grants, emphasizing the importance of the U.S. semiconductor supply chain for emerging applications in automotive and IoT industries as well as global trends like 5G, AI, high-performance computing (HPC), and edge computing.