Vijayawada: As part of its mission to create a dumpyard-free state, Swachh Andhra Corporation has prepared a roadmap for effective reuse of dry waste produced across the state. As waste segregation into dry and wet waste is already being done, the dry waste will be sent to industries with boilers and kilns to replace coal. When used in appropriate proportions, dry waste can generate the same amount of heat required in certain industries, such as cement manufacturing units.

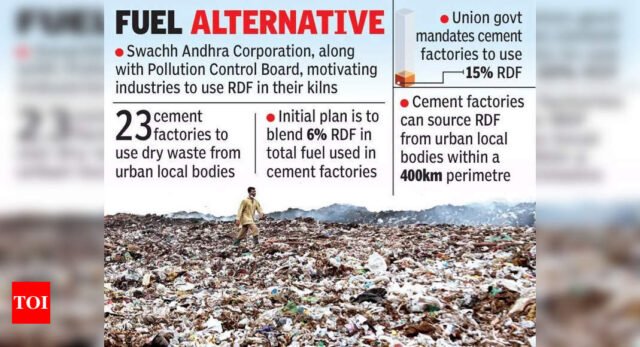

The dry waste segregated from the garbage collected in urban local bodies is ideal for use in cement factories, said Kommareddy Pattabhiram, chairman of Swachh Andhra Corporation. “Solid waste management rules framed by the Union govt in 2018 also prescribes that cement factories must use not less than 15% of refuse derived fuel (RDF) generated from urban local bodies within a 400km perimetre. Despite having a number of cement factories in the state, the usage of RDF, which is nothing but dry waste, is very minimal not only in cement factories but also in other industries where it can be used,” he said.

Swachh Andhra Corporation is also focusing on turning dry waste into alternative fuel, which can be used in boilers that need high calorific value. Pattabhiram said there are some models where dry waste can be converted into fuel pellets, which can generate the same heat as coal. “We are examining all models to see how the waste can be reused. If we can convert the waste into energy, we will achieve the dual purpose of becoming a dumpyard-free state and also create wealth from waste, making it a sustainable model,” he added.

Pattabhiram further said that the usage of RDF in cement factories is prevalent in developed countries. He noted that European countries use 44% RDF in kilns, whereas the usage in the USA is about 20%. “We are starting with a 6% target in the first year and aiming to scale it up to 15%,” he said.

The dry waste segregated from the garbage collected in urban local bodies is ideal for use in cement factories, said Kommareddy Pattabhiram, chairman of Swachh Andhra Corporation. “Solid waste management rules framed by the Union govt in 2018 also prescribes that cement factories must use not less than 15% of refuse derived fuel (RDF) generated from urban local bodies within a 400km perimetre. Despite having a number of cement factories in the state, the usage of RDF, which is nothing but dry waste, is very minimal not only in cement factories but also in other industries where it can be used,” he said.

Swachh Andhra Corporation is also focusing on turning dry waste into alternative fuel, which can be used in boilers that need high calorific value. Pattabhiram said there are some models where dry waste can be converted into fuel pellets, which can generate the same heat as coal. “We are examining all models to see how the waste can be reused. If we can convert the waste into energy, we will achieve the dual purpose of becoming a dumpyard-free state and also create wealth from waste, making it a sustainable model,” he added.

Pattabhiram further said that the usage of RDF in cement factories is prevalent in developed countries. He noted that European countries use 44% RDF in kilns, whereas the usage in the USA is about 20%. “We are starting with a 6% target in the first year and aiming to scale it up to 15%,” he said.